To my most faithful readers, to those who, in short, have missed my articles and have even asked what happened to me, I am back to base. On the eco-à-porter Facebook page a few days ago I published a post related to the reasons for my absence, which obviously added to other commitments but I think you don’t care about that. So, my return post is dedicated to the experience that led me to Castelfranco Veneto, in the North-East of Italy, to follow a very intensive denim seminar organized by ISKO, the global denim giant we talked about many times for its commitment to sustainability.

The ‘ISKO Denim Seminar’, held on 18th and 19th March in Castelfranco Veneto, in the province of Treviso, in the Creative Room, the Italian center of ISKO specialized in design and style research, is part of the broader ISKO I-SKOOL training project, aimed at students of fashion schools, their teachers and designers specializing in denim, who are offered laboratories and experience in the field, as well as the opportunity to enter the contest that each year is developed around a particular theme.

And it is from the Creative Room that comes the theme on which the finalists of the competition, coming from the most important fashion schools in the world, work constantly followed by the Isko creative team and the seminar is in this sense an important opportunity for meeting, exchange and training. Having followed it closely both days, I can say that it is just like that!

The full immersion was inaugurated by Rosey Cortazzi, ISKO Global Marketing Director, who, by presenting ISKO and its role as global denim producer, has focused heavily on sustainability, not hiding that it is a complex, multi-faceted discourse that it embraces all the phases of production of the fabric, starting from the main ingredient, which is certified organic cotton. Ironic Rosey when, talking about sustainability, she compared it to adolescent sex, that is everyone talks about it but few do it. Touché!

After a brief excursus on the history of denim introduced by Jacques Stuyt, ISKO Senior Sales Manager, the lesson ‘From field to fabric’ by Baris Ozden, ISKO R&D Manager, examined the steps that transform raw cotton in yarn and then in fabric, an elaborate process subjected to the strictest quality controls to comply with the certifications that ISKO enjoys and that cover the entire Life Cycle Assessments (LCA), a globally recognized methodology used to evaluate and quantify the environmental footprint of a product throughout its entire life cycle, from the raw material to the finished product. I then asked Baris what the term ‘sustainability’ means to him, naturally applied to his work and the answer was ‘responsible innovation’, that is a continuous and responsible improvement in all stages of the production, from spinning to finishing and this responsibility has to be also transmitted to the end customer.

Because, in fact, if we think about it, ‘sustainability’ may mean everything and nothing, especially when we think of a production as complex as that which transforms a raw material into something much more complex, like a yarn, like a fabric. The factors at stake are many and then ‘responsibility’ I believe is the right term: responsibility in cultivation (of the cotton plant, in this case), responsibility in processing, responsibility towards those who cultivate it or collect it or, again, work it. And so on.

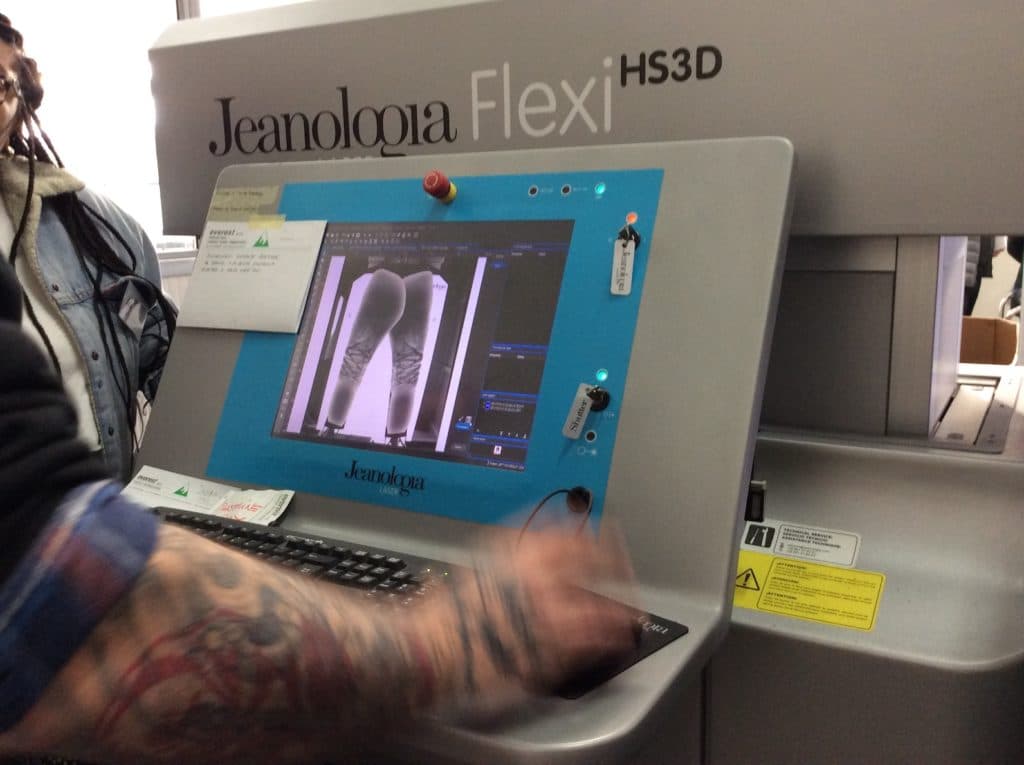

Other interesting lessons, from the transformation of the fabric into the finished garment to the modeling, from the finishing to innovation in a sustainable key, were held both by the internal members of the Creative Room and by the official ISKO partners, such as Reca Group, the Italian company specialized in labels, tags and packaging, Riri Group, manufacturer of zippers, Jeanologia, a Spanish company that develops eco-efficient technologies in the finishing sector, therefore treatments and workings with lasers for example. Of Jeanologia I saw in action, at the Everest industrial laundry, some last generation machinery able to speed up or replace all the vintage treatments on the garment, also realizing all-over prints.

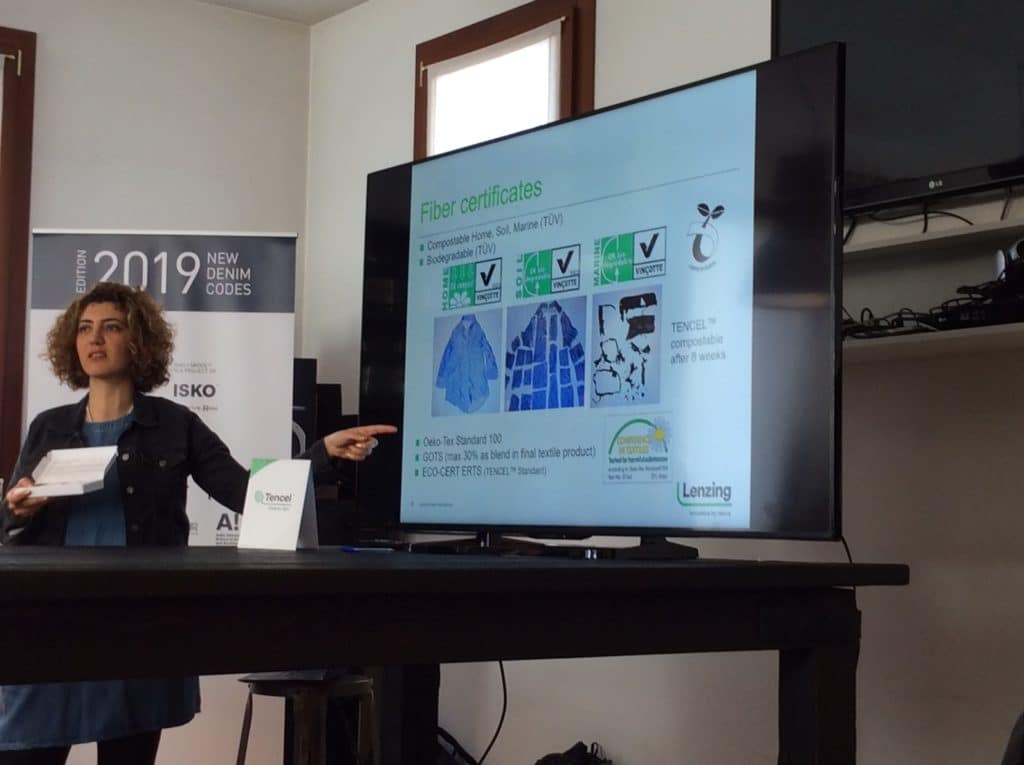

Among the partners also Lenzing, the Austrian company of which we have spoken several times for its commitment in the sustainable (or should we say responsible) production of Modal fibers, viscose and Lyocell, with the detailed presentation of Hale Öztürk, Project Manager of Lenzing, who explained the different production phases of the fibers whose raw material comes from the pulp of the wood, coming from certified forests (therefore not ancient and endangered forests) with the supervision of the NGO Canopy. The pulp byproducts then have different destinations, such as xylan which then becomes xylitol for chewing gum or acetic acid used in the food industry, while the ‘closed cycle’ production system allows the monitoring of emissions and chemical recovery rates.

Last but not least important event of the seminar, the workshop with Marina Tonella, something different from the classic presentations, aimed at stimulating the students’ creative development, touching their way of observing, speaking, listening. Because to best express your creativity, you have to open your mind, looking inside and out.

With my head full of things, I went back to my blog and the boys to their schools, where they will continue to work for the contest that will have its final moment next July in Berlin during Fashion Week. We will talk about it again. Meanwhile, I would like to conclude with the words of some of the finalists, to whom I asked what “sustainability” means to them and how they would like to apply it to their future work.

Danielle Cinelli, 24 years old, from Los Angeles, Denim Design Professional: “Sustainability means to me finding ways to improve production of goods one step at a time. A sustainable company or production doesn’t happen overnight, it takes baby steps each day. Sustainability is reducing water, chemicals and scraps of denim/fabric. It’s about being smart on pattern making to have least amount of wastage. Using quality fabrics to ensure a long product cycle. Sustainability is about extending the products lifecycle whether is creating a new product from it, reselling it or a sample sale. Sustainability is being transparent so your consumer knows where it came from & steps.

I strive to learn more about the laser technology & the more eco friendly processes & machines. I believe this is something that is going to be in demand & the new production way.

I want to work under some companies to grow & learn. Someday I hope to have my own made in the USA eco line. Key components would be eco denim fabrics, little to no water & no chemicals. I want it to be made in the USA so we have a quality eco friendly line that is fully transparent.

Carmen Moser, 25 years old, from Berlin, Denim Design Professional: “The first thing that comes to mind when I think of sustainability is durability, something that lasts long, and therefore the quality of the materials used to make a certain product. But a sustainable fashion for me also involves the concept of genderless, something open to all, without gender barriers. And then, the protection of workers’ rights and consumer awareness come to mind; one of the purposes of my work is and will be precisely to educate people about responsibility and in general I think that this is one of the main tasks of every designer “.

Mao Xiuquing, 33 years old, from Hangzhou, Zhejiang, Cina, Denim Design Professional: Speaking little English, Mao wanted to communicate the concept of sustainability with images relating to her interpretation of the theme of the contest ‘New denim codes’, which of course I will not show for obvious reasons but which I can summarize by saying that the idea is that of ‘nothing is thrown away’, ‘cherish everything’ as in Chinese tradition and that here adapts to a multidimensional vision of cuts and folds adapted to the shape of the body, welcoming it.

![Mono[PA6] by Freitag, a prova di economia circolare](https://eco-a-porter.com/wp-content/uploads/2024/05/freitag_monopa6_hero_master_16zu9_fin_01.2_0-218x150.jpg)