Sorry for my absence, I am working on other articles and projects and unfortunately I am not yet a trine but today that I have some time I want to share with you a beautiful discovery that I made during the research for one of the pieces I told you a moment ago.

Preparing an article on 3D printing in the fashion industry, I came across Israeli designer Danit Peleg, a pioneer of 3D printed fashion, the first designer in the world, in 2015, to create an entire collection using home 3D printers for her design project degree from Shenkar College of Engineering and Design in Ramat Gan, Tel Aviv district. The following year she was invited by the Paralympic Games to design a 3D printed dress for Amy Purdy, a two-legged amputee dancer, who performed at the opening ceremony, until she was named by the BBC in 2019 one of the hundred most influential women in the world.

The designer sees in 3D printing, not only a tool to offer new opportunities in fashion and inspire young creatives, but also and above all a technology that can drastically reduce waste and pollution, providing a sustainable alternative for the future in a sector among the most impacting. “Imagine a world, says Danit Peleg, where people buy digital files of 3D printed clothes, download them and make them at home, tailor-made, without producing waste”. So she and her team work tirelessly, both to improve the quality of available materials, making sure they resemble existing high-quality fabrics, such as silk and linen, and by partnering with 3D printer companies to make the creative process smoother possible.

But how did Danit’s adventure begin? With an internship in New York, where she worked for a fashion house, helping them in the realization of their 3D collection, a real undertaking, because they used large industrial printers and the situation was very stressful, because each dress cost about 20,000 dollars and it was mostly of sculpture-dresses made of a fragile plastic that broke with every movement of the models. Back in Israel, Danit receives a necklace made with a 3D printer from a friend and she is enlightened: if a necklace can be printed with a home printer, why not a dress?

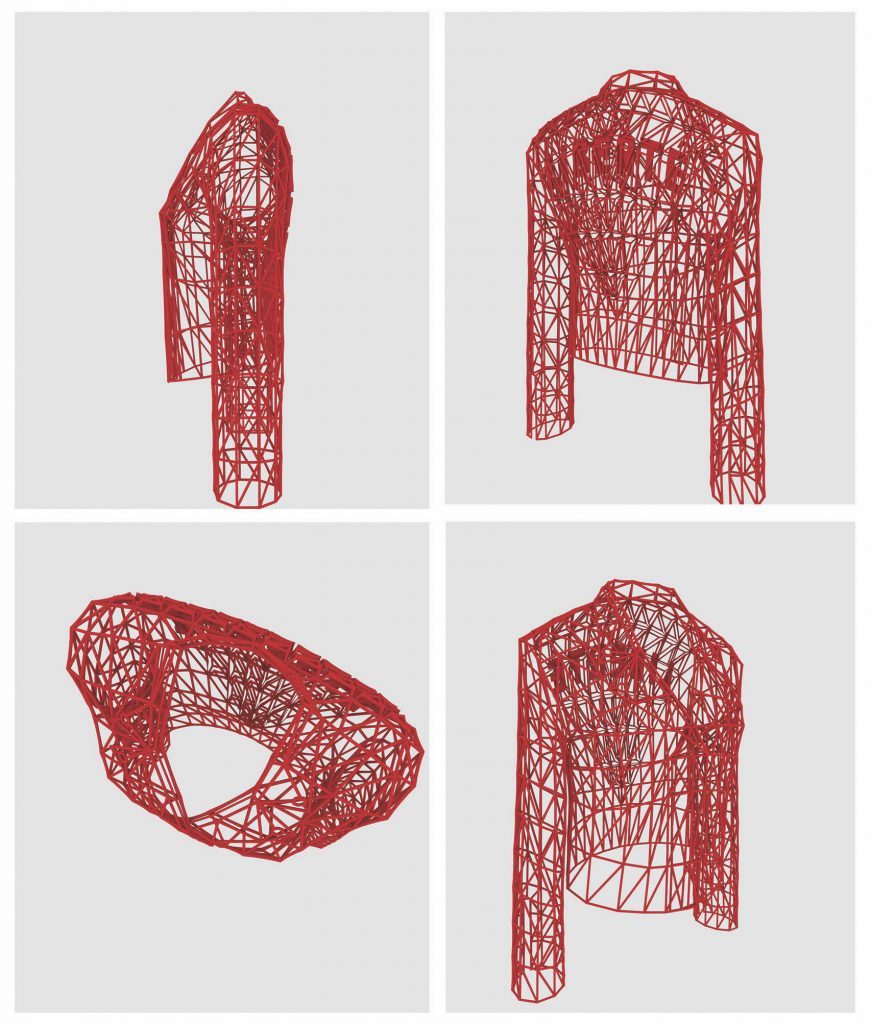

The path of the designer, after the collection created for the degree thesis, continues between incessant research and the creation of other collections, almost always inspired by classical art, such as ‘The Birth of Venus’, the second collection, which also includes the outfit I mentioned earlier for the Paralympic dancer Amy Purdy and a jacket that is available on the designer’s website and can be customized and printed to order.

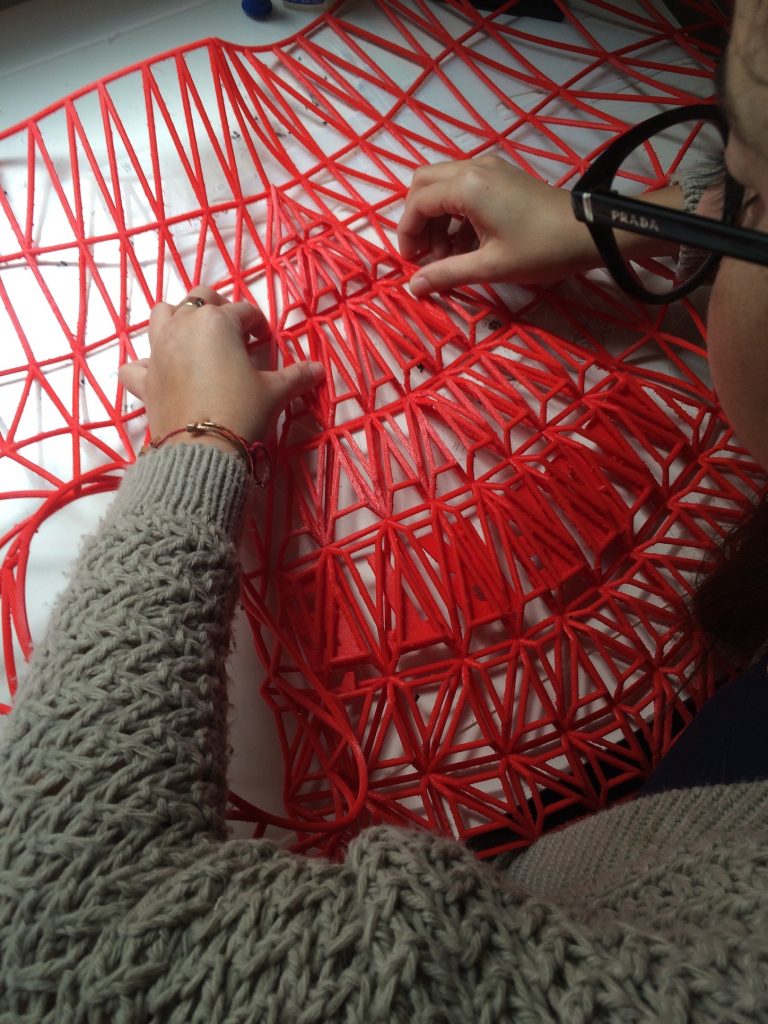

Since each single jacket takes about 100 hours to print, the garment, called ‘Imagine’, is part of a limited edition of only 100 pieces, each numbered and sold for $ 1,500. The outside of the jacket is 100% 3D printed and is attached to a fabric lining; it is also possible to choose a word to print, always in 3D, on the back. The jackets are printed in Spain but assembled and shipped from Tel Aviv, where Danit lives.

Unlike traditional manufacturing, the 3D printing process produces zero waste and no additional materials. Danit mainly uses Filaflex, one of the most elastic materials on the market today. It is very strong but also soft to the touch and allows, when combined with other fabrics with a flexible structure, to obtain a fluidity and a pleasant sensation in contact with the skin.

After creating the garment on the computer, the designer opens everything on a 3D modeling software, so that each part adapts to the print size, with the possibility of choosing a specific size, even for each single piece: if for example a person has a small size but long arms, you can change the length of the sleeves without altering the other measurements.

It is undoubtedly a fascinating process, which radically changes the creative approach but also that of purchasing; and if one day it were just like that, if we all had the opportunity to become designers, to choose, buy and download the file of a dress and print it at home? You’d like it?

Certainly a lot of waste would be avoided. We would have a super transparent and very short supply chain. We would know all about the materials. But the role of creatives would also change. Of the shopping experience and much more. Not to mention the end-of-life of the materials used for printing, which are still bio-plastics, although in this field too, research is making progress with sustainable alternatives from agricultural waste. We’ll see.

One day, anyway. For now, let’s think about it.

![Mono[PA6] by Freitag, a prova di economia circolare](https://eco-a-porter.com/wp-content/uploads/2024/05/freitag_monopa6_hero_master_16zu9_fin_01.2_0-218x150.jpg)